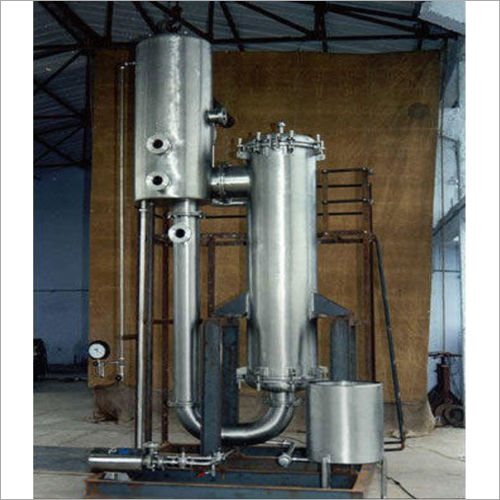

Multiple Effect Evaporator

Product Details:

- Pressure 0.1 to 1.5 kg/cm (G) Steam Pressure

- Sealing Gasketed, Leak Proof

- Condition New

- Process Multiple Effect Evaporation

- Power Source Electric

- Application Used for concentration of solutions in pharmaceutical, chemical, food and dairy industries

- Material Stainless Steel 304/316

- Click to View more

X

Multiple Effect Evaporator Product Specifications

- 220-415 V / 50 Hz

- 15 kW - 125 kW

- Multiple Effect Evaporation

- Electric

- 0.1 to 1.5 kg/cm (G) Steam Pressure

- Used for concentration of solutions in pharmaceutical, chemical, food and dairy industries

- Customized as per requirement

- Stainless Steel 304/316

- Depends on capacity, typically 2-10 tons

- New

- Gasketed, Leak Proof

Product Description

Multiple effect evaporators and agitated thin film dryer plant is a device that effectively evaporates water by using the heat from steam. It boils water in a series of vessels, each one under a lower pressure than the one before it. Because of its higher sensitivity and viscosity, our offering is generally utilised with fluids that are challenging to handle. Two essential parts make up this multiple effect evaporators and agitated thin film dryer plant like a jacketed shell and a rotor that rotates rapidly inside the shell. Our offering places the feed inside the top mechanism.

Customizable Performance for Diverse Applications

With up to six effects and a wide feed range, this evaporator can be tailored to suit the specific needs of your process-whether in pharma, food, or chemicals. The modular design enables precise control over concentration ratios and process efficiency, enhancing output quality for various industries.

Advanced Design and Hygiene Features

Constructed from premium Stainless Steel 316 and featuring a mirror-polished interior, this system guarantees sanitary processing and easy cleaning with CIP compatibility. The PLC-based control panel ensures precise operation, real-time monitoring, and simplified maintenance.

Efficient Utility and Energy Usage

Low steam consumption, adaptable to feed rates and effects, provides operational cost savings. The system is compatible with different cooling technologies and combines energy-efficient operation with robust pressure management, making it suitable for continuous industrial usage.

FAQ's of Multiple Effect Evaporator:

Q: How does the Multiple Effect Evaporator improve concentration processes?

A: The system uses multiple evaporating stages to optimize energy use, significantly increasing the concentration ratio-up to 1:10. This enhances product yield and lowers operational costs, supporting efficient solution concentration across various industries.Q: What types of solutions can be processed using this evaporator?

A: It is ideal for concentrating solutions in pharmaceutical, chemical, food, and dairy applications, accommodating a wide range of viscosities and material properties due to its customizable design.Q: When is on-site installation service available for this equipment?

A: On-site installation is provided as part of the service offering within India. Scheduling is coordinated post-purchase to ensure efficient setup and commissioning tailored to the client's requirements.Q: Where can this evaporator be installed and operated?

A: The unit's adaptable dimensions and modular setup allow installation in various industrial settings, including factories and processing plants, with support for customized space configurations.Q: What benefits does CIP compatibility offer during operation?

A: CIP (Clean-in-Place) compatibility ensures thorough internal cleaning without disassembly, minimizing downtime and maintaining product purity and safety by facilitating routine hygienic maintenance.Q: What process control features are included?

A: The evaporator is equipped with a PLC-based panel featuring a digital display, which allows operators to monitor and adjust critical parameters, automating the system for efficient and consistent operation.Q: How is operational safety ensured?

A: Safety is maintained through design pressure management (up to 3 kg/cm2), leak-proof gasketed sealing, and robust stainless steel construction, all supported by advanced control and monitoring systems.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email